0086-139-59890092

0086-139-59890092 info@chinadiamant.com

info@chinadiamant.com

Diamond Drill Bits

Diamond Drill Bits Diamond Drum Wheels

Diamond Drum Wheels Diamond Fickert Abrasives

Diamond Fickert Abrasives Diamond Frankfurts

Diamond Frankfurts Diamond Finger Bits

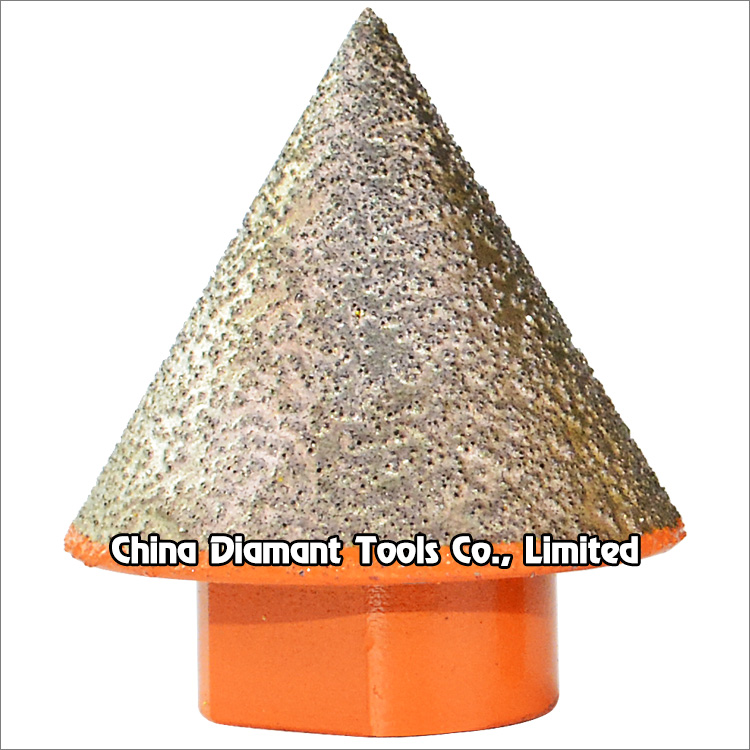

Diamond Finger Bits Diamond Grinding Bits

Diamond Grinding Bits Diamond Grinding Cup Wheels

Diamond Grinding Cup Wheels Diamond Grinding Shoes

Diamond Grinding Shoes Diamond Grinding Discs

Diamond Grinding Discs Diamond Milling Wheels

Diamond Milling Wheels Diamond Plugs

Diamond Plugs Diamond Polishing Pads

Diamond Polishing Pads Diamond Polishing Discs

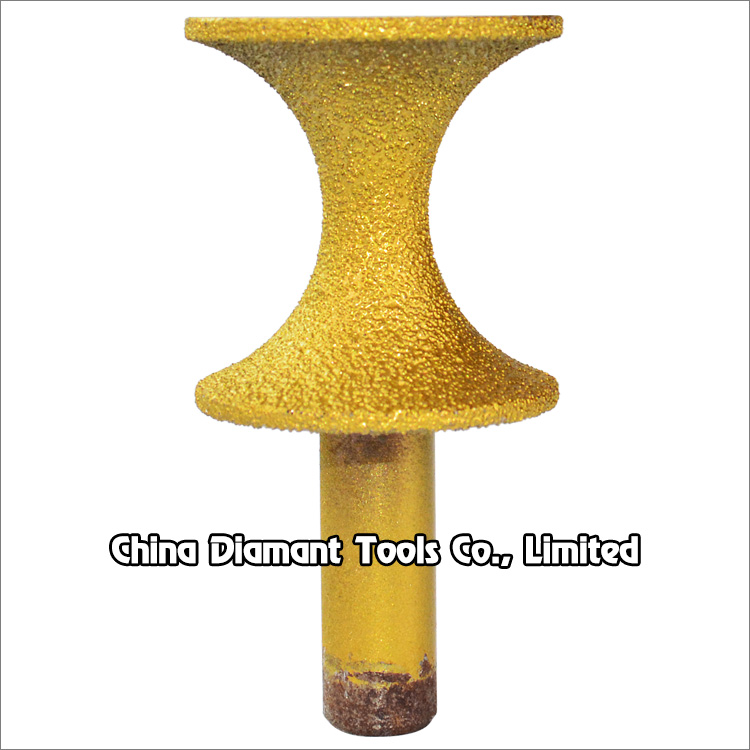

Diamond Polishing Discs Diamond Profile Wheels

Diamond Profile Wheels Diamond Rollers

Diamond Rollers Diamond Saw Blades

Diamond Saw Blades Diamond Segments

Diamond Segments Diamond Squaring Wheels

Diamond Squaring Wheels Diamond Wire Saw

Diamond Wire Saw Stone Processing Tools

Stone Processing Tools Concrete Processing Tools

Concrete Processing Tools Ceramic Processing Tools

Ceramic Processing Tools Electroplated Diamod Tools

Electroplated Diamod Tools Vacuum Brazed Tools

Vacuum Brazed Tools Hot-press Sintered Tools

Hot-press Sintered Tools High-frequency Welded Tools

High-frequency Welded Tools Laser Welded Tools

Laser Welded Tools

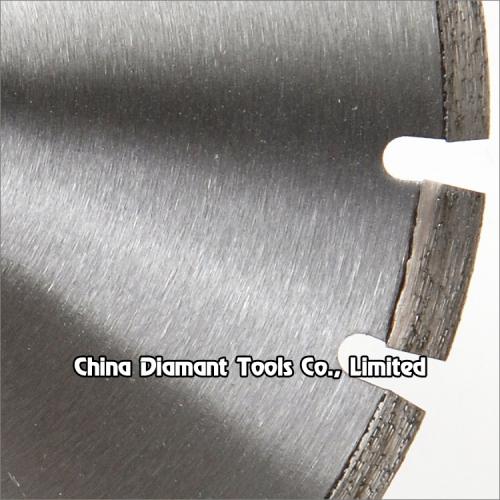

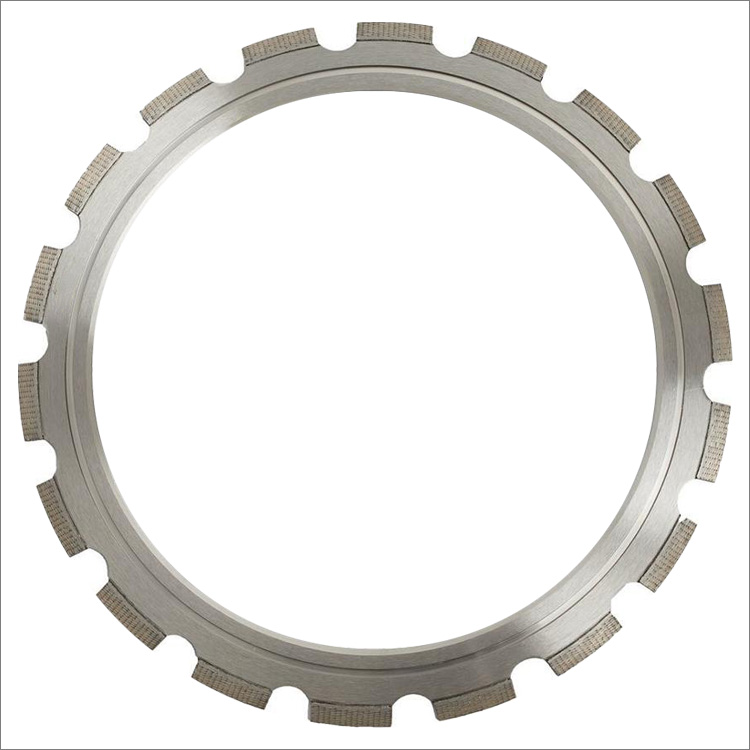

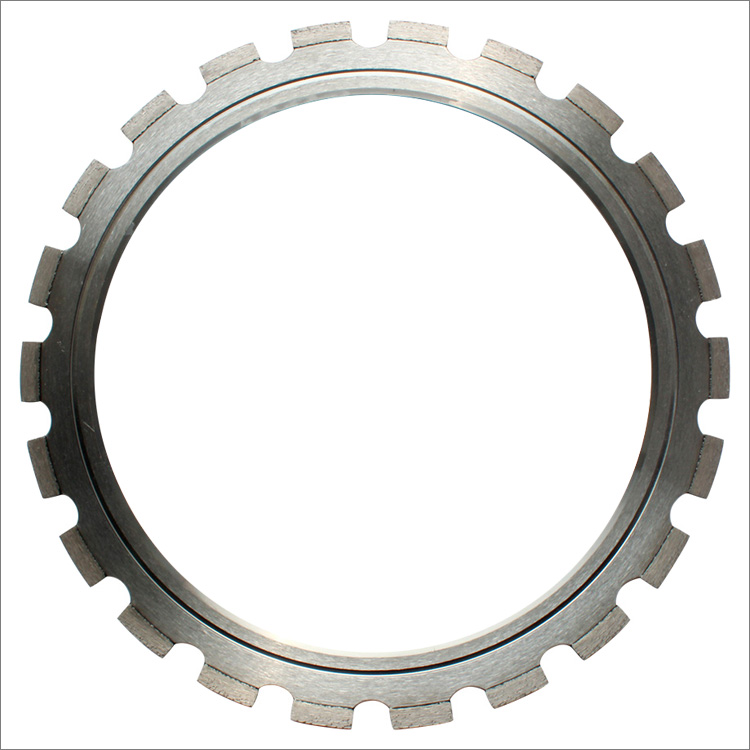

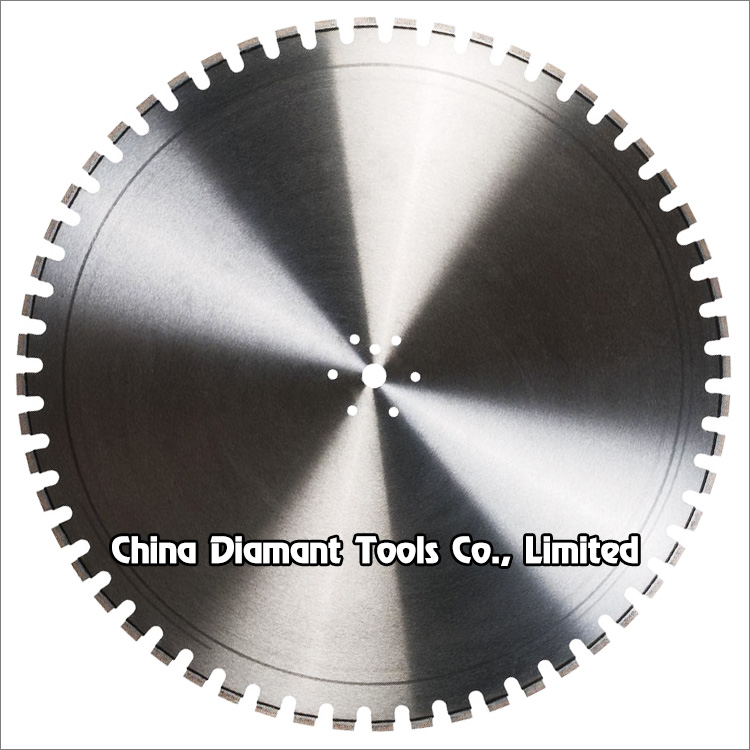

Diamond saw blades for asphalt cutting - laser welded with low protection segments

Diameter: 300mm-800mm

Bore: 25.4/50/60mm

Segment height: 10mm

Segment: normal flat with low protection teeth

Production process: laser welded

Diamond saw blades for asphalt cutting - laser welded with low protection segments

With Drop Segments (Low Protection Teeth)

Asphalt Saw Blades are used for cutting asphalt and asphalt over concrete roadways, also suitable for cutting green concrete and other abrasive materials with maximum performance and longevity.

This type of diamond blade is usually for roadway construction, demolition and parking lot applications.

Our asphalt cutting diamond saw blades come laser welded, the U slot gullet design allows for quick and efficient debris removal to provide fast cutting action and prevent segment loss.

Wet cut only with sufficient water!

Suit for hand held circular saw, gas powered saw, walk behind saw.

Diameter: 12"(300mm)-32"(800mm), segment height: 10mm.

Bore size: 25.4mm, 50mm, 60mm or as per demand.

Welding method: laser welded.

|

Code No. |

Diameter (mm/inch) |

Segment Size (mm) |

Segment No. (pcs/set) |

|

SBA-01-300 |

300mm(12") |

40x3.0x10 |

21 |

|

SBA-01-350 |

350mm(14") |

40x3.2x10 |

24 |

|

SBA-01-400 |

400mm(16") |

40x3.6x10 |

28 |

|

SBA-01-450 |

450mm(18") |

40x4.0x10 |

32 |

|

SBA-01-500 |

500mm(20") |

40x4.2x10 |

36 |

|

SBA-01-600 |

600mm(24") |

40x4.6x10 |

42 |

| SBA-01-650 | 650mm(26") | 40x4.6x10 | 46 |

| SBA-01-700 | 700mm(28") | 40x4.6x10 | 50 |

| SBA-01-750 | 750mm(30") | 40x4.8x10 | 54 |

| SBA-01-800 | 800mm(32") | 40x4.8x10 | 57 |

The above specifications & photos are only for reference, other specification may be available as per demand.

Remarks:

What is the difference between between concrete and asphalt blades?”

The easiest answer is the BOND of the blade. The bond is the metals

that hold the diamonds in place. The bond consists of metal powder.

The powder can be a mixture of a variety of metals such as cobalt,

tungsten, nickel, and copper. Asphalt is softer then concrete so the

metals that are used in the bond are the harder metals (cobalt &

tungsten) For concrete the bond consists of softer metals (nickel &

copper)

Another difference between the design of Asphalt vs Concrete blades

is the core. Asphalt blades have a segment that will go further into

the core, either a drop segment, wedge segment, radial segment, or

tungsten or carbide kickers. The reason for this is because asphalt

is more abrasive then concrete. Without the added features, your

blade will undercut and thin out, because of the abrasive compounds

grinding on the blade during cutting.

NEWSLETTER

NEWSLETTER 0086-139-59890092

0086-139-59890092