0086-139-59890092

0086-139-59890092 info@chinadiamant.com

info@chinadiamant.com

Diamond Drill Bits

Diamond Drill Bits Diamond Drum Wheels

Diamond Drum Wheels Diamond Fickert Abrasives

Diamond Fickert Abrasives Diamond Frankfurts

Diamond Frankfurts Diamond Finger Bits

Diamond Finger Bits Diamond Grinding Bits

Diamond Grinding Bits Diamond Grinding Cup Wheels

Diamond Grinding Cup Wheels Diamond Grinding Shoes

Diamond Grinding Shoes Diamond Grinding Discs

Diamond Grinding Discs Diamond Milling Wheels

Diamond Milling Wheels Diamond Plugs

Diamond Plugs Diamond Polishing Pads

Diamond Polishing Pads Diamond Polishing Discs

Diamond Polishing Discs Diamond Profile Wheels

Diamond Profile Wheels Diamond Rollers

Diamond Rollers Diamond Saw Blades

Diamond Saw Blades Diamond Segments

Diamond Segments Diamond Squaring Wheels

Diamond Squaring Wheels Diamond Wire Saw

Diamond Wire Saw Stone Processing Tools

Stone Processing Tools Concrete Processing Tools

Concrete Processing Tools Ceramic Processing Tools

Ceramic Processing Tools Electroplated Diamod Tools

Electroplated Diamod Tools Vacuum Brazed Tools

Vacuum Brazed Tools Hot-press Sintered Tools

Hot-press Sintered Tools High-frequency Welded Tools

High-frequency Welded Tools Laser Welded Tools

Laser Welded Tools

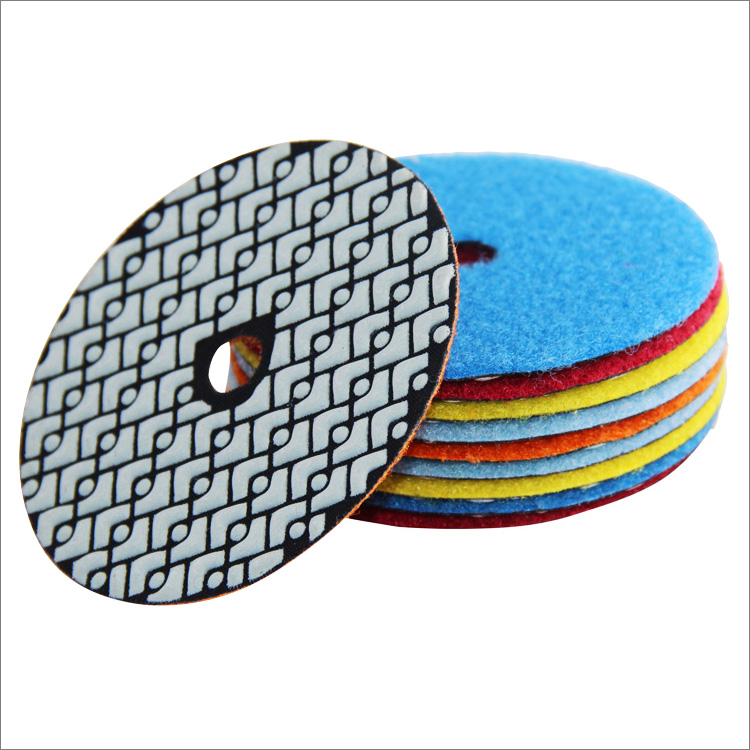

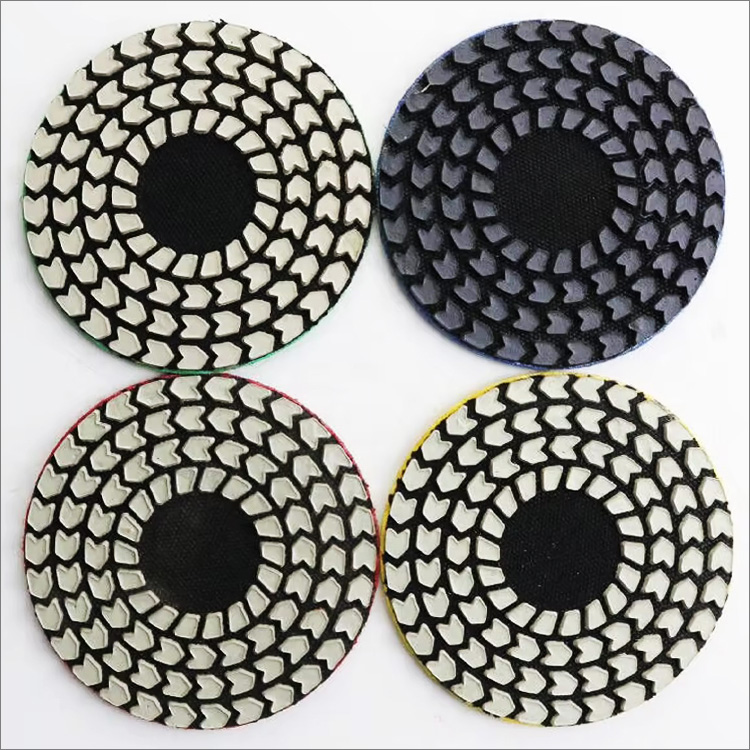

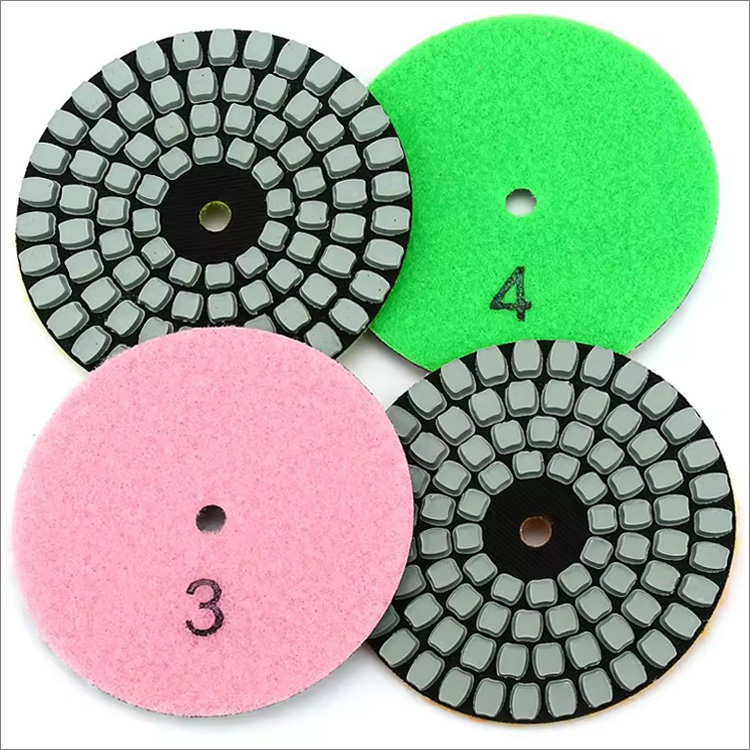

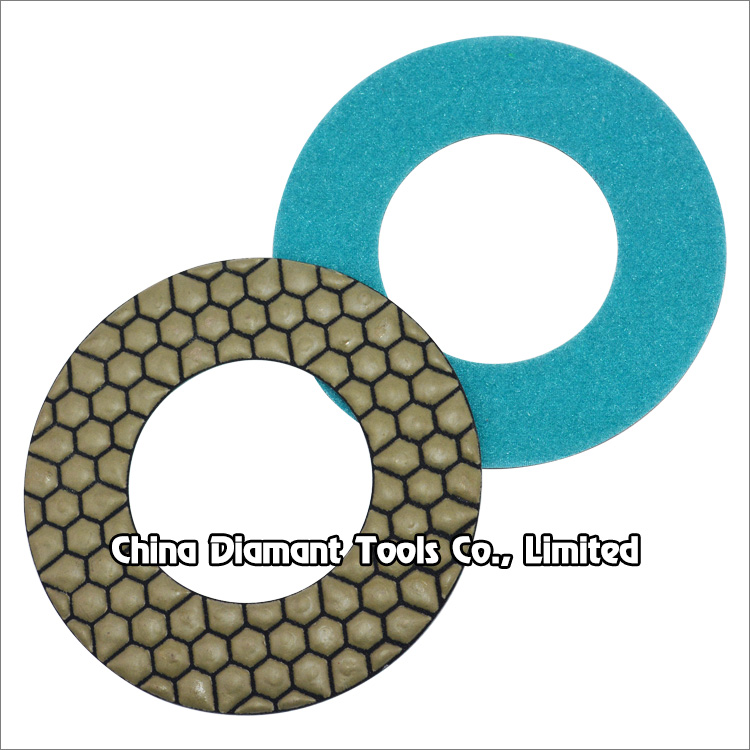

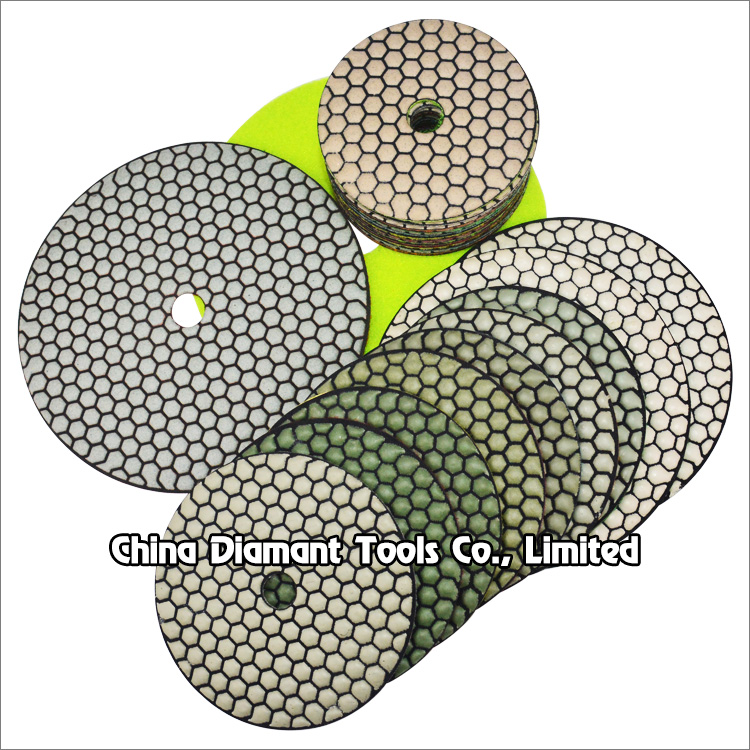

Flexible diamond dry polishing pads resin bond for stone granite marble

Diameter: 80mm, 100mm, 125mm

Bond type: resin

Thickness: 2.1mm

Grit: #50-#3000

Holder: velcro

Using type: dry

Flexible diamond dry polishing pads resin bond for stone granite marble

This type diamond polishing pads 8pcs set for dry polishing of stone contoured and straight edges, they are made up of high quality diamond powder and resin binder materials, and designed through scientific formula and advanced process technology, with good flexibility.

It's easy and fast polishing various stones such as granite, marble, sandstone, limestone, slate, travertine, basalt, artificial stone with quick speed, high glossy degree and long working life without scratch, no burning and color dropping on stone.

The pads backed with nylon Velcro cloth and color coded for easy identification which can be easily installed and quick changed on the Angle grinder, Floor polisher, Air grinder, Polisher tools etc.

Diameter 3", 4", 5", 6", 7", grind or polish from coarse to fine, diamond grits includes 50#, 100#, 200#, 400#, 800#, 1500#, 3000# and Buff.

| Code No. |

Diameter |

Thickness | Grit No. |

| DPP-D11-080 |

80mm(3") |

2.1mm |

50# - 3000#, Buff(black/white) |

| DPP-D11-100 |

100mm(4") |

2.1mm |

|

| DPP-D11-125 |

125mm(5") |

2.1mm |

How to polish stone by

using dry diamond pads:

1) Always wear protection for eyes, nose, hands, safety glass,

gloves and apron. Never use high speed grinder and exceed rated RPM.

2) Secure/fasten the stone, it should not slide while polishing.

3) Attach velcro backer pad and polishing pads to polisher evenly

else it may wobble. Start polishing with grit 50 at low rpm, adjust

rpm as needed. Verify the entire polished stone surface has same

level of smoothness before moving to next grit. If not, continue

polishing with same grit. Generally above grit 400 grit surface is

scratch free.

4) Repeat step 3, for each higher grit one by one starting grit 50

till 3000. Dont skip any grit in between. Most of the stone will

show shine starting grit 800. If one still sees scratches beyond

grit 800 and 1500, it is a sign that step 3 is not followed

correctly in lower grits.

The above specifications & photos are for reference, other specification may be available as per demand.

NEWSLETTER

NEWSLETTER 0086-139-59890092

0086-139-59890092